The digital oilfield has evolved over the last decade. What started as sending a remote-controlled machine into the field has grown to encompass a broader range of front and back-office processes. Streaming real-time data from far-flung pipelines and drilling operations has opened up new opportunities for oil and gas decision makers. Forward-thinking O&G executives are now implementing the same high-tech tactics that track heavy equipment and monitor production performance into new lines of business. Donned the “digital oilfield,” this emerging arena leverages tech like IoT, AI, and intelligent process automation (IPA) to gather and react in real time to data streaming in from the field. But monitoring field activity is just one piece of the puzzle. Combined with powerhouse intelligent process automation, O+G professionals have an unbeatable recipe for improving oilfield operations.

What is intelligent process automation in oil + gas; and how can it benefit the industry?

Intelligent process automation (IPA) is a new way of thinking that transforms a toilsome, error-prone manual operation into a fully digitized enterprise. Robotic process automation (RPA), workflow automation, and machine learning are just a handful of technologies that serve as the backbone of IPA. By using these new tools, oil and gas companies can take in a massive amount of real-time data and autonomously infuse it into each and every internal process. By taking on the responsibility of repetitive, mundane, and high-volume tasks, IPA helps high-value workers focus on solving more complex problems.

Analysts calculate that a commitment to digital transformation could generate an extra $1.6 trillion in value for the industry by 2025, but even the most forward-thinking O+G initiatives are still hobbled by outdated systems. Legacy infrastructure remains a stalwart brick wall when it comes to clinching the bottom line-boosting advantages of automation. But, oil and gas is an industry yoked by pricing pressures where bottom line costs of new initiatives are a chief concern. New technology needs to be more than a dazzling shiny object, but must drive true value for oil and gas operations. What are the main benefits of intelligent process automation in the digital oilfield?

- Make faster decisions by placing a wealth of knowledge at your fingertips

- Plan and zone complex well sites more quickly

- Minimize unplanned downtime of heavy equipment

- Monitor fluctuations in barrel pricing 24/7 and adjust operations accordingly

- Mitigate ebbs and flows of labor availability

- Standardize how field operators execute their job responsibilities

- Generate more accurate production forecasts

- Predict problems before they spin out of control

- Improve worker safety

- Foster interdepartmental collaboration

The global coronavirus pandemic reduced energy demand in surprising ways: shuttered office buildings consume fewer resources and the “couch commute” is far closer to home. For an industry whose digital maturity has stagnated for decades, COVID-19 catapulted O&G companies into a digital transformation fervor. Tech-savvy professionals needed new ways to control remote operations and shore up reporting benchmarks for meeting low-carbon emissions targets. The industry was not immune to the work-from-home trend; in one study, O&G executives cited stymied “knowledge exchange amongst employees” as the biggest remote working challenge.

The oil and gas industry ranks as one of the most regulated industries worldwide. Energy executives are on a constant mission to keep up with fluctuating regulations impacting pipeline activity and worker safety and to integrate them into worldwide operations. The mercurial nature of it all has outwitted even the most adept regulatory official.

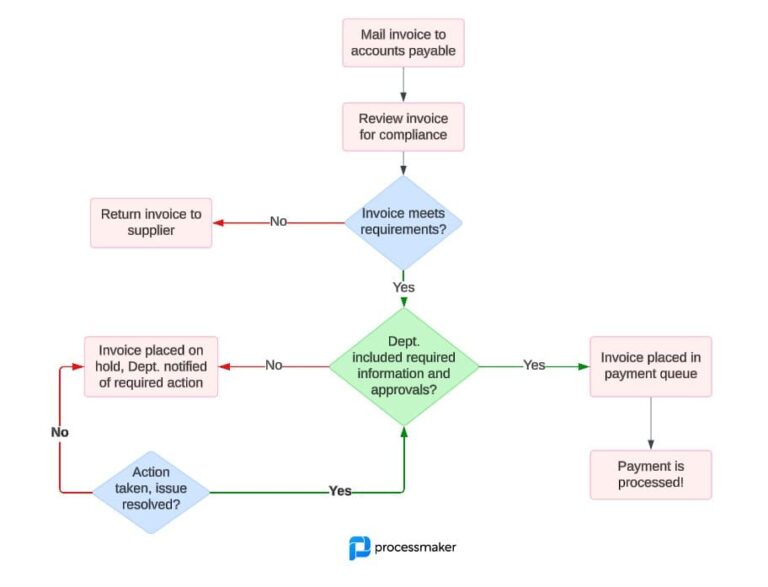

This burdensome regulatory responsibility is a prime candidate for automation—a technology that thrives on nitty-gritty rules. Instead of updating internal procedures with an onerous fine-tooth comb, automated workflows do the job for you. Whether a regulatory update is a sweeping change or a slight modification, you can easily adjust rules-based workflows to reflect the change.

Intelligent process automation can help operators act on real-time information to optimize field performance. Waiting for a written report from on-site personnel delays decision making, allowing problems in the field to snowball into equipment downtime or hazardous incidents. Automation helps serve as your eyes and ears; virtually transporting decision makers to a site even if they’re in a home office thousands of miles away.

Who are the prime candidates for automation in oil and gas?

With the multi-layered structure of oil and gas operations, there are many areas that could benefit from a digital transformation overhaul. Trying to implement automation into every aspect in one fell swoop is a fool’s errand. After all, 70% of digital transformations fail because organizations simply bite off more than they can chew. To combat this risk and emerge victorious, start by streamlining key processes within important business activities one at a time. Here are four places to start.

Improve efficiency in well planning

By using automation in well planning, your team can improve overall strategy, improve safety, and reduce evaluation time. IPA technology can bring together cross-disciplinary data like geospatial, tabular surveys, and flow controls: as well as cross-department knowledge from geoscientists and drilling engineers. Instead of juggling isolated software tools, rolled paper maps, and a platoon of heavy equipment, operators can deploy smarter equipment that folds real-time data into a robust decision-making engine. Internal processes involved in the project can automatically deploy as different waypoints are met.

Optimize upstream production

In the age of IoT, even wellheads and pump stations are signing online. Remote controlled drilling tools don’t only get the job done—they gather troves of data along the way—data that can be sent back to HQ to improve decision making. Giving this critical machinery a voice inundates operators with a deluge of intel—but how do you decide what information is the most valuable? Smart operators are automating key data points to control wellhead variables like gas lift insights and flow rate models to optimize production. Engineers stationed on the other side of the world have full visual into site activity and can make adjustments to key controls in real time.

Reduce skyrocketing downtime costs

Process automation is a helpful tool for reducing unexpected (and expensive) oil field downtime. Some reports estimate that oil and gas organizations lose an average of $49 million per year due to unplanned downtime.

California Resources Corporation wanted to put an end to the over-the-top revenue drain experienced in the field. Home to a 60,000 square foot warehouse of vital parts and equipment to service oil wells, it was challenging to map components to their associated well. CRC created a Google-like search tool linking together various inventory sources to standardize indexing criteria and streamline procurement. They were able to repair wells more quickly and increase production by minimizing equipment downtime. Overall, automation saved this repair juggernaut $1 million in warehousing costs.

Banish time-draining paper-based processes

Midstream companies yoked by legacy systems are often a labyrinth of accounting platforms. Plant accounting might use one option, while the financial team in contract management operates under a completely different software package. Each system is blind to the activities of the other, leading to redundancies and knowledge gaps.

Siloed business activity can break operational efficiency. P2 Energy Solutions, an oil and gas financial software company out of Denver, Colorado, used workflow automation to banish this very threat. Lease approvals, production volume management, geological offerings, and other service processes were scattered across 100 different software solutions. To promote the sharing of data across platforms and eliminate repetitive tasks, P2 layered an automation platform over their existing legacy environment. This strategy enabled them to centralize incoming data streams from land management to geospatial data and execute processes from one comprehensive platform.

Intelligent process automation can envelop all organizational processes into a bird’s-eye end-to-end view. From production forecasts to well planning and on-site equipment operation, every system in your business can ultimately benefit from IPA.

Ready to get started with your automation game plan?

Intelligent process automation plays a critical role in the lasting success of the oil and gas industry. As infrastructure grows and becomes more and more complex, a streamlined, dashboard-style view into global operations becomes increasingly important. As more and more oil field machines continue to sign online, operators will have endless access to valuable data points. Intelligent process automation is what makes this next-gen data actionable.